Product Brief

The Neutron Moisture Meter is a cutting-edge radiometric device designed for precise, real-time measurement of moisture in bulk materials stored in silos, bunkers, or on conveyors.

Using neutron interaction technology, it delivers highly accurate results even in challenging industrial conditions, making it ideal for industries like mining, cement, fertilizer, coal, and food processing.

Product

Description

Moisture measurement is critical for quality control and efficient process management. The Neutron Moisture Meter works on the principle of neutron scattering and absorption, utilizing a fast neutron source and a thermal neutron detector.

Since hydrogen atoms are directly related to moisture content, the system measures hydrogen concentration to determine water percentage in bulk materials.

With robust construction, long-term electronic stability, and advanced evaluation software, the Neutron Moisture Meter provides reliable, continuous, and maintenance-friendly operation.

Product

Applications

Coal, potash, iron ore, bauxite

Measures moisture content in soil for construction and foundation stability assessment.

Used for precise soil moisture measurement to optimize irrigation and crop management.

Coal, potash, iron ore, bauxite

Non-destructive measurement of moisture content in bulk food materials, aiding in quality control, shelf-life optimization,

Maintaining optimal moisture levels to prevent material degradation, clumping, or spoilage, ensuring better flowability.

Key

benefits

Ideal for bulk solids and powders.

Measures moisture deep inside bulk material, not just at the surface.

Instant data for better process control.

Suitable for silos, bunkers, and belt conveyors.

Resistant to abrasion and industrial environments.

Automatic correction ensures accurate weight % moisture, even with varying bulk density

Radiation source is securely encapsulated, meeting international safety standards.

Installation

Types

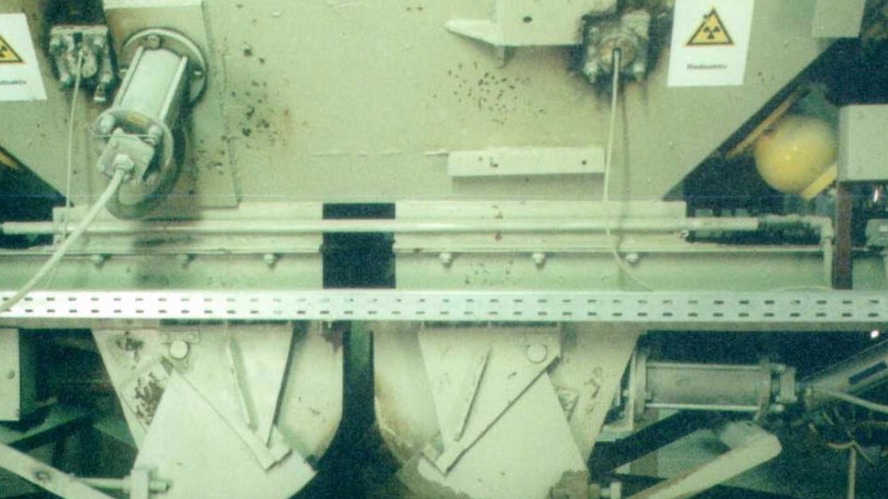

- Silo / Bunker Installation: Source and detector housed in a protection pipe inserted into the silo for full-depth analysis.

- Surface Probe Installation: Ideal for highly abrasive materials or when silos are unavailable, mounted from outside silo walls or conveyor belts.

- Conveyor Belt Monitoring: Installed beneath or above conveyors to measure moisture in moving bulk materials.

Mechnical & Technical

Specifications

Americium-Beryllium (sealed stainless-steel capsule)

Solid scintillation crystal with photomultiplier for long-term stability

Polyethylene with boron enrichment for neutron capture

Wide range depending on calibration (typical ±1% accuracy)

Integrated gamma source and detector for automatic correction

Why Choose Our Neutron Moisture Meter?

Unlike traditional moisture measurement techniques, neutron-based measurement provides true bulk material analysis rather than surface-level detection. This ensures more reliable quality control, reduced energy costs, and optimized production efficiency.